Growing Bacillus can be fun! Enzymes

In our introductory blog on Bacillus, we shared some of its unique features that has made it a microorganism of choice for many commercial applications in Bio-Pharma, Probiotics, Plant Nutrition, Biocontrol and other emerging markets. Along with its spore forming tendencies, Bacillus are capable of producing a wide range of natural products including enzymes, acids, and vitamins when it has access to the right resources and growth environment. In this blog, we will provide a brief overview of enzymes, discuss microbial enzyme production with Bacillus and some key factors that can drive improved fermentation performance in commercial applications.

Overview of Enzymes

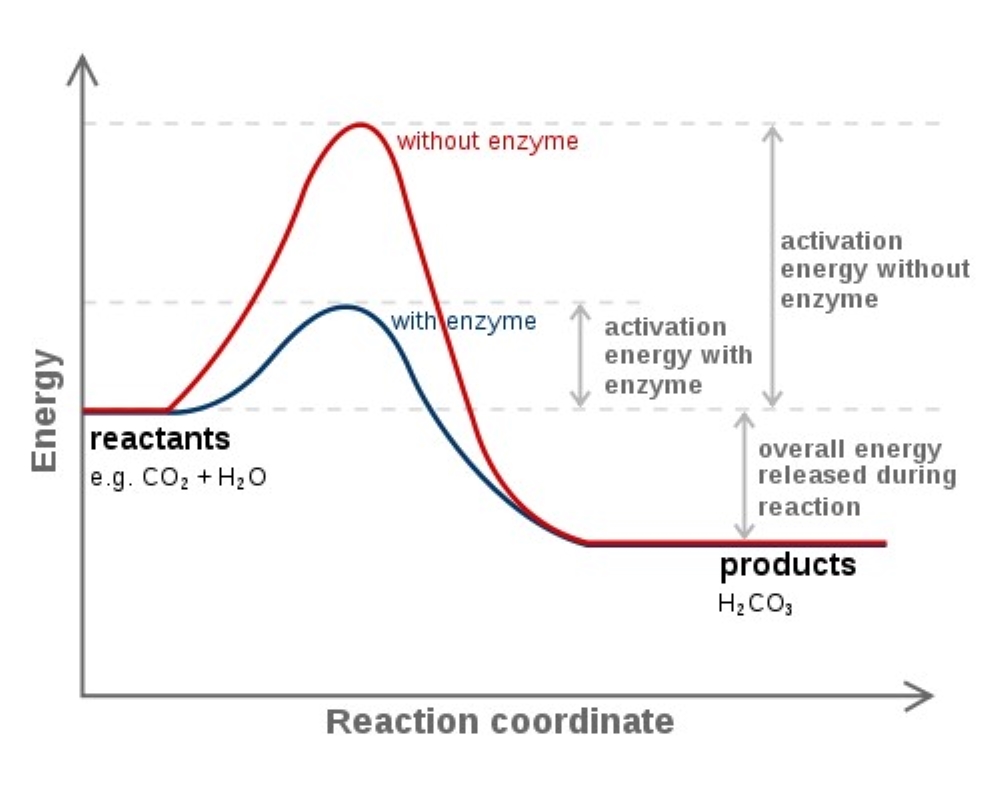

Enzymes are biological molecules (proteins) that act as catalysts and within the mild conditions of temperature, pH, and pressure of the cells, carry out chemical reactions at an amazingly high rate. They are characterized by their remarkable efficiency and specificity. Enzymes accelerate chemical reactions by lowering the activation energy required to turn reactants into products as depicted in Figure 1.

Sources of enzymes

All enzymes originate from living organisms. The conventional way of discovering enzymes is by growing organisms and then isolating enzymes in some way from parts of plants, animal organs, inside of microorganisms, or in their immediate environment. Not surprisingly, the first enzymes used by humans were enzymes isolated from animal and plant extracts, such as the protease papain from papaya fruit or rennet from calves’ stomachs. However, most technical enzymes nowadays originate from microorganisms.

Enzymes produced by microorganisms are called microbial enzymes. Some microbes are adapted to live under extreme conditions of temperature and pH. Microbial enzymes that are active under abnormal temperature or pH conditions have industrial benefits because they are more stable than enzymes from plants and animals. For example, organisms that produce enzymes are able to function at higher temperatures, which reduces the possibility of contamination in industrial scale reactions of long duration. Microbial enzymes can be produced through fermentation techniques in a cost-effective manner with less time and space requirement. In addition, because of their high consistency, process modifications and optimization can be done very easily.

Commercial applications for microbial enzymes

Bacillus are capable of producing various types of enzymes. Common species of Bacillus used in industry for enzyme production are B. subtilis, B. clausii, B. amyloliquefaciens, B. halodurans, B. megaterium, B. stearothermophilus, and B. thuringiensis just to name a few.

Many types of industries utilize enzymes to aid in the generation of their products. Examples of industrially relevant enzymes produced by Bacillus are proteases, amylases, and xylanases. Proteases are enzymes which break down proteins and peptides. This enzyme is commonly used in washing powders, the food industry, leather processing, and in pharmaceuticals. Amylases are enzymes that convert starch and glycogen into simple sugars. Therefore, amylases useful in the production of syrups, reduction of turbidity to produce clarified fruit juice for longer shelf life, solubilization and saccharification of starch in the brewing and biofuels industries, delaying the staling of baked goods, reduction of starch viscosity in papermaking, and as a digestive aid in supplements. Xylanases break apart the polyssacharide xylan into xylose, which is a monosaccharide, found in plant cell walls. This enzyme is used for fruit juice clarification, providing brightness to paper, and improving nutritional properties of silage and grain feed.

Fermentation Performance Improvement

Fermentation is a method for generating enzymes for industrial purposes, which involves microorganisms. These microorganisms are able to produce enzymes externally or internally. Externally produced enzymes can be recovered by methods such as centrifugation. Whereas, internally produced enzymes require more complex downstream processing because the microbial cells must be lysed, then the suspension is processed to extract a concentrated and pure enzyme final product. Bacillus can secrete enzymes externally which is a massive benefit allowing for easier downstream processing.

Typical success criteria for producing enzymes include high enzyme activity, short fermentation time, and minimal side activity (i.e. other types of enzymes being produced). Enzyme activity is a measure of the active enzyme present and is determined by measuring the amount of product formed, or substrate consumed in a reaction at a given time.

There are two ways to produce enzymes microbially: solid state fermentation or submerged fermentation. Solid state fermentation is a process where the metabolites are generated by microorganisms grown on a solid support with nutrients added. Submerged fermentation is performed in bioreactors with liquid media containing nutrients the microorganism can use. Typically solid state fermentations are used for fungi and mold whereas submerged fermentations are ideal for yeast and bacteria such as Bacillus. A challenge for submerged fermentation of Bacillus is that adequate aeration and mixing must be maintained.

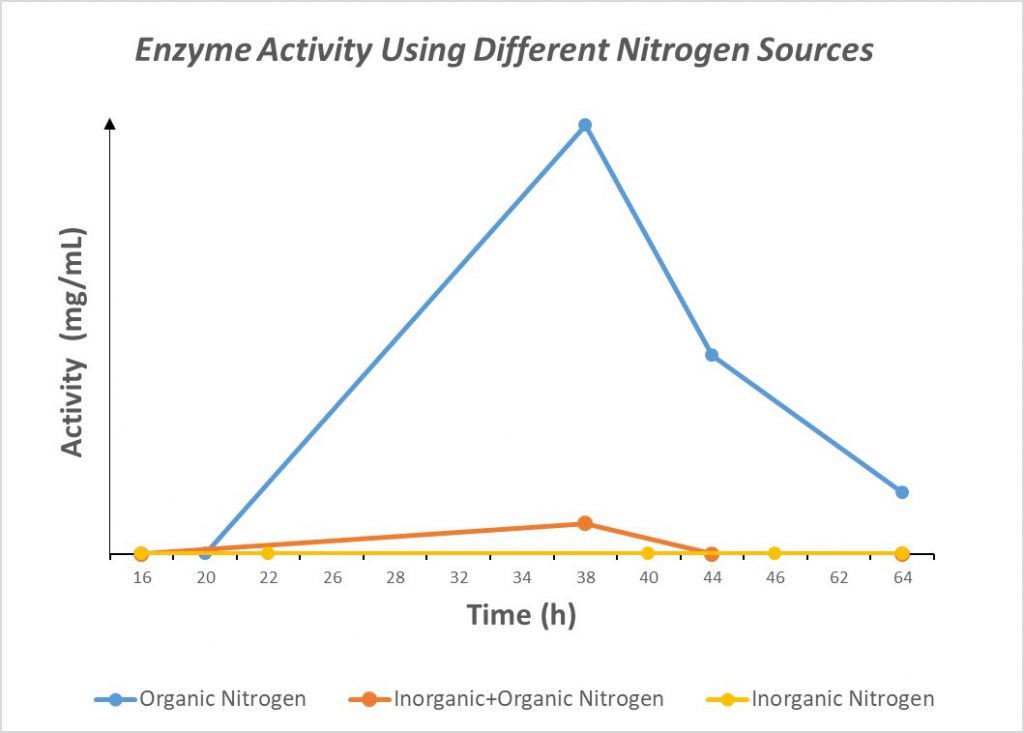

Additionally, providing adequate nutrition for the organism to produce enzymes is necessary. When selecting the components of the growth medium, it is possible to guide the cells towards the production of certain products such as enzymes. Nitrogen source in the fermentation media is an important factor for the production of enzymes. This is because microbes metabolize nitrogen sources to produce peptides and amino acids for enzyme production.

Nitrogen can come in organic and inorganic forms. It has been found that organic sources result in better production of certain enzymes from Bacillus such as proteases. This was further confirmed in our lab where we tested the effect of different nitrogen sources to enzyme activity. Sensient yeast extracts and peptones were used as organic nitrogen sources and ammonium sulfate was used as an inorganic source. Media with organic nitrogen components showed greater enzyme activity than that of media containing inorganic nitrogen as can be seen in Figure 2.

Summary

Understanding the optimal conditions for fermentation, performing media optimization studies, and scaling up to production volumes can be resource-intensive and time-consuming tasks. Though a number of variables can impact microbial enzyme production, our experience has shown that selecting the right media mix can have the most significant impact on the fermentation performance. Working with a partner with detailed knowledge of the nutrients and fermentation conditions suitable for each application can accelerate efforts towards achieving your business goals in a relatively short amount of time.

References:

Nigam, P. (2013). Microbial enzymes with special characteristics for biotechnological applications. Biomolecules, 3(3), 597-611.

Raddadi, N., Crotti, E., Rolli, E., Marasco, R., Fava, F., & Daffonchio, D. (2012). The most important Bacillus species in biotechnology. In Bacillus thuringiensis biotechnology (pp. 329-345). Springer, Dordrecht.

van Dijl, J., & Hecker, M. (2013). Bacillus subtilis: from soil bacterium to super-secreting cell factory.

Saggu, S. K., & Mishra, P. C. (2017). Characterization of thermostable alkaline proteases from Bacillus infantis SKS1 isolated from garden soil. PloS one, 12(11), e0188724.

Raveendran, S., Parameswaran, B., Ummalyma, S. B., Abraham, A., Mathew, A. K., Madhavan, A., … Pandey, A. (2018). Applications of Microbial Enzymes in Food Industry. Food technology and biotechnology, 56(1), 16–30.